Automation doesn’t replace people! It removes low-value work so teams can scale.

For many teams, robotics still comes with a misconception: “If we automate, our people will get replaced.”

In reality, the future of automation in manufacturing is human-centered.

At Konnected Technology, we see this every day: when robots take on repetitive, heavy, or low-value tasks, teams finally get the bandwidth to focus on skilled work, quality, and continuous improvement. Throughput rises not because robots replace workers, but because workers can perform at their highest level.

This shift is fueled not just by traditional robotics, but by a fast-growing category: cobotics: robots designed to work with people, not instead of them.

Understanding the Difference: Robotics vs. Cobotics

Traditional Robotics

Traditional industrial robots are:

- Large, powerful, and often fenced off

- Designed for high-speed, high-volume operations

- Best suited for tasks like welding, heavy palletizing, or precision machining

They create massive efficiency gains, but they operate in isolation where humans typically cannot enter the work cell while the robot is running.

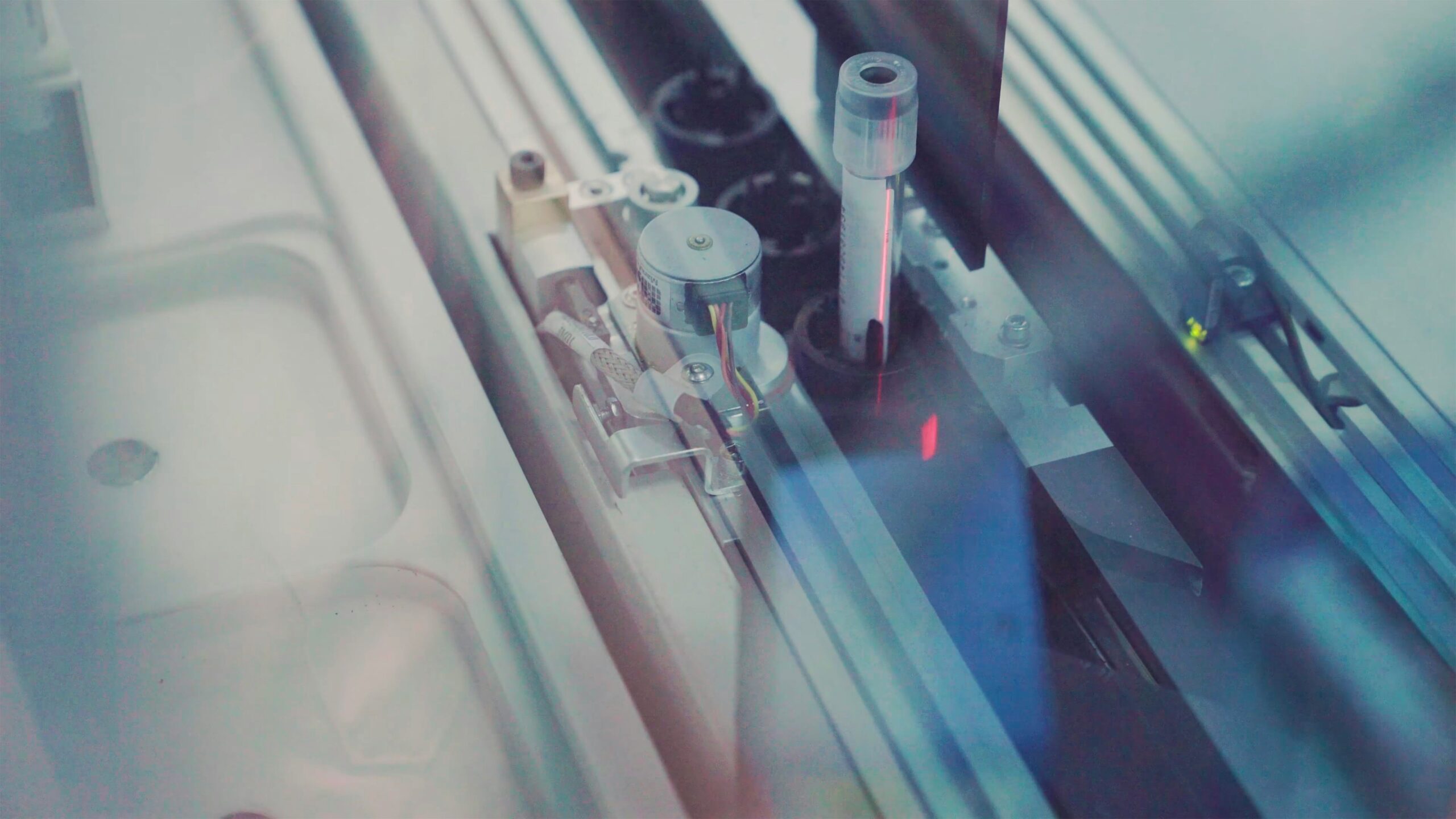

Collaborative Robots (Cobots)

Cobots are fundamentally different. They are:

- Safe to operate near humans without caging

- Equipped with sensors, force detection, and smart controls

- Lightweight and easy to redeploy

- Designed for tasks that benefit from human oversight + robotic consistency

Cobots don’t replace human involvement; they augment it by handling repetitive motions, tight tolerances, or ergonomic risks.

Human + Robot Collaboration in Manufacturing

The real power of cobotics emerges when humans and robots share the workflow:

Robots handle the repetitive tasks

Such as:

- Assembly assistance

- Pick-and-place

- Machine tending

- Screwdriving, packaging, or labeling

Humans handle the skilled tasks

Such as:

- Quality inspection

- Complex decision-making

- Troubleshooting

- Setups, adjustments, and problem-solving

Rather than eliminating jobs, cobots elevate workers into higher-value roles. Employees gain new technical skillsets while the cobot drives consistent throughput.

Safety, Flexibility & Speed: Why Cobots Fit Modern Operations

1. Built-In Safety

Cobots use force limits, proximity sensors, and smart collision detection to operate safely around people. This eliminates complex safety fences and allows space-efficient workstation design.

2. Rapid Deployment

Most cobots can be installed and programmed in days instead of months.

This reduces downtime and accelerates ROI.

3. Adaptable to Many Tasks

Cobots excel in environments where product types or workflows change often.

They can be:

- Reprogrammed on the fly

- Moved between stations

- Integrated into existing manual processes

Their flexibility fits perfectly with modern, mixed-model manufacturing environments.

Why Cobots Are Ideal for Phased Automation

Many operations hesitate to automate because they believe it requires a full, facility-wide overhaul. Cobots break that barrier.

Start Small

Deploy a single cobot for a repetitive station like machine tending or assembly.

Then Scale

As teams get comfortable and productivity rises, expand to additional stations.

Standardize the Workflow

Over time, cobots create predictable processes that pave the way for broader automation (AMRs, AGVs, vision systems, etc.).

Cobots act as a gateway technology enabling organizations to modernize their operations without massive upfront investment or cultural disruption.

The Bottom Line: Cobots Strengthen Your Workforce

Cobotics improve throughput not by replacing people, but by freeing them from low-value tasks that drain time and energy. The result is a safer, more efficient, more engaged workforce that is supported by automation that scales with demand.

Ready to See How Cobotics Can Elevate Your Operation?

Konnected Technology helps teams deploy robotics and cobotics strategically with a focus on improving flow, productivity, and worker experience.

→ Request a Cobotics Assessment

Visit us at konnectedtechology.com and discover where collaborative automation can make an immediate impact on your throughput.