“It’s not as expensive as you think.” Let’s reframe automation costs.

The perception: automation = huge cost

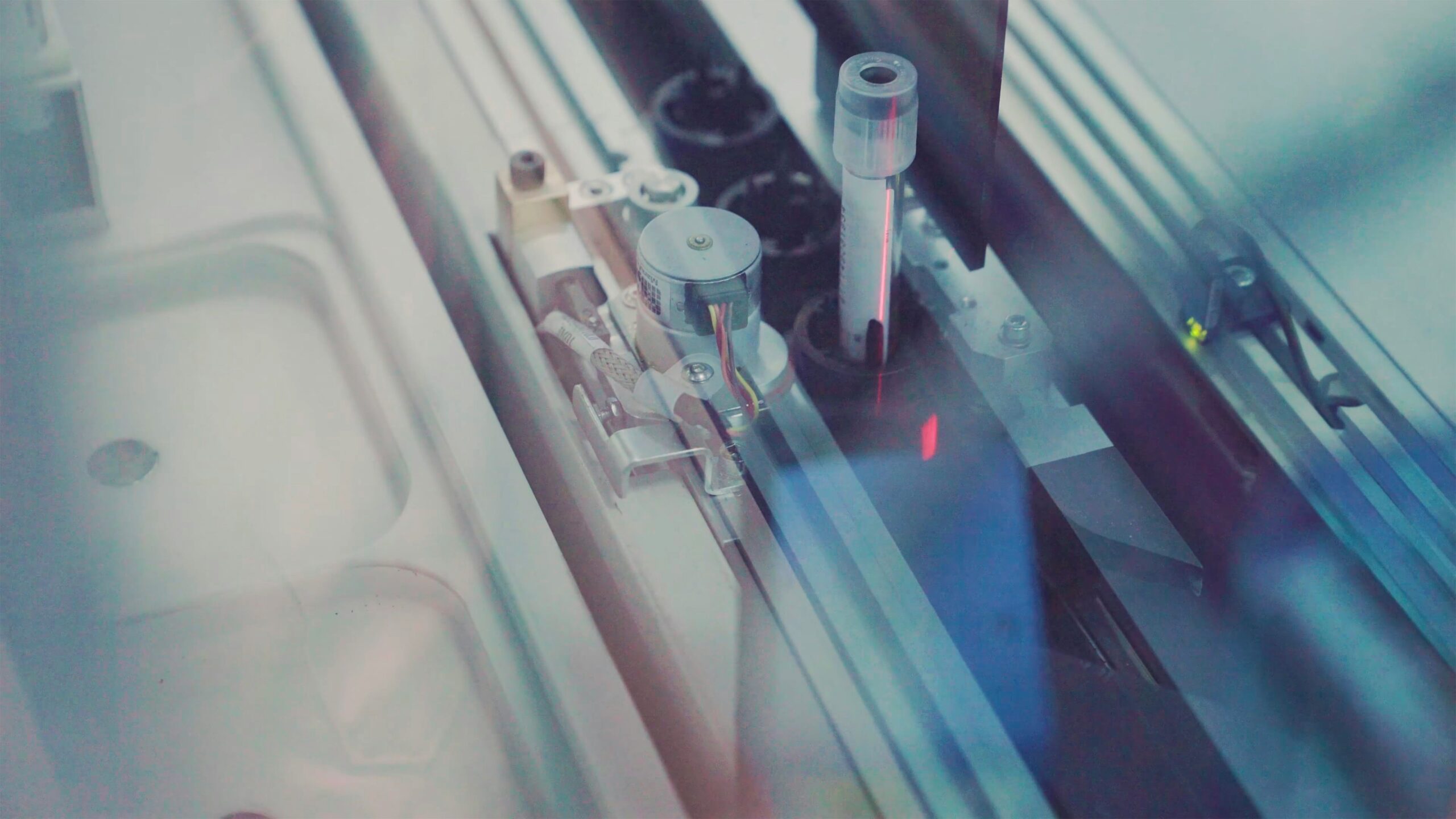

When many business owners hear “automation,” images of expensive robots, full-line rebuilds, and years of downtime can pop into mind. That perception is limiting. “We can’t afford it right now” can stop innovation before it even begins. At Konnected Technology, our goal is to help you re-frame that limiting belief: automation doesn’t have to be prohibitively expensive, and you can take it step by step.

Rental & leasing: faster approval, quicker start

One of the easiest ways to overcome the cost barrier is to rent or lease equipment instead of purchasing up front. Because rentals or leases typically fall under operational expenditures (OpEx) rather than major capital expenditures (CapEx), they often go through quicker internal approvals. Teams can start using production-driving automation sooner, without waiting for the full capital budget.

For instance, instead of one big check for robots and conveyors, you can make predictable monthly payments and roll out in phases. This reduces risk and gives you flexibility.

Buy back or repurpose: leverage what you already own

You don’t always have to start from zero. Many companies have existing equipment lying around. Older conveyors, manual stations, legacy machines, these can all be bought back, traded in, or repurposed into an automation project. By layering automation onto what you already have rather than tearing everything out, you reduce the initial cost significantly.

Konnected Technology works with you to identify existing assets that can be reused, upgraded, or integrated so that your automation investment goes further.

Start small & scale up: proof today, growth tomorrow

Another barrier is the fear of “all-or-nothing” implementation. But the smarter path is to start small: pick a pilot line, integrate one smart cell, automate one process. Once you see the ROI, you scale. This phased approach allows you to:

- Test performance and validate savings

- Build internal stakeholder buy-in

- Use cash flow from early gains to fund further automation

- Avoid large upfront risk

For example, you might deploy a single AMR (autonomous mobile robot) or a guided assembly cell this quarter, see labor savings and throughput gains, then move into multiple lines next year.

Real numbers, real confidence

Imagine this scenario: your facility needs a new automated guided vehicle (AGV) and associated control system. Rather than buying for $500K upfront, you can lease for $12K/month for 36 months. Instead of waiting a year to see full benefits, you begin seeing improved throughput, fewer errors, and labor redeployment right away. Over time, your cost of ownership stays predictable, and the barrier to entry drops.

Because you began sooner and scaled up, you hit payback faster, and you don’t have to wait for “the perfect moment.”

Your automation partner, not just a vendor

At Konnected Technology, we believe in being a partner: helping you evaluate cost structures (buy, lease, rental), identifying what you already own, designing a phased rollout, and ensuring the implementation delivers measurable business outcomes.

If cost concerns have kept automation on the back burner, we’re here to help you take the next step.

Reach out to learn which leasing, rental, or buy-back options could work for your business.