Most logistics issues aren’t labor shortages, they’re invisible bottlenecks. Automation exposes and eliminates them.

When productivity drops inside a warehouse or manufacturing plant, the go-to explanation is almost always the same: “We just need more people.”

But more often than not, the real issue isn’t headcount, it’s flow.

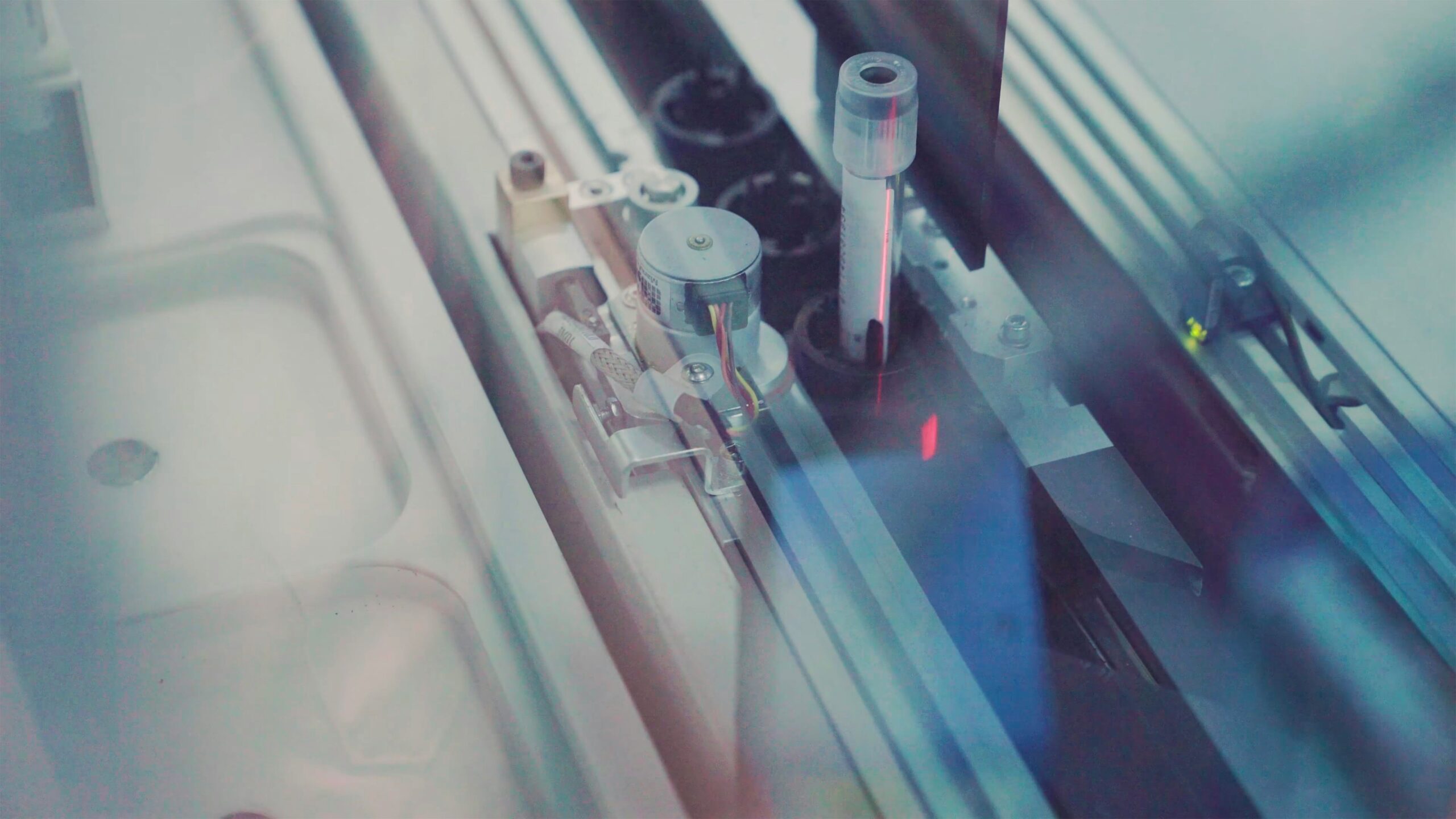

Every operation has hidden friction points that quietly drain throughput. They’re small enough to miss in daily operations, but large enough to slow an entire facility. This is where autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) shine. By standardizing and automating material movement, they reveal inefficiencies that human-centric workflows naturally hide.

Let’s break down where these invisible bottlenecks occur and how modern automation eliminates them.

Common Hidden Bottlenecks in Warehouses & Plants

Even well-run operations deal with friction that rarely shows up on dashboards:

1. Travel Time Waste

Operators walking thousands of steps per shift for materials, tools, or components.

This silent time-sink is one of the largest drains on productivity.

2. Unbalanced Workstations

Some stations starve while others drown in work-in-process (WIP) because material arrival is inconsistent or dependent on manual judgment.

3. Backlogs at Dock or Staging Areas

When goods arrive faster than they move inward, receiving becomes a chokepoint.

4. Priority “Firefighting” Moves

Hot parts, last-minute line calls, and emergency replenishments disrupt planned movement and create cascading delays.

5. Excessive Forklift or Tugger Dependence

One shared piece of equipment becomes a bottleneck anytime demand peaks or drivers are unavailable.

These issues aren’t caused by labor shortages, they stem from workflow design, not workforce size.

Where AMRs vs. AGVs Shine in Removing Friction

AMRs and AGVs automate movement, but each excels in different scenarios:

AGVs: The Best Choice for Predictable, High-Volume Routes

AGVs follow fixed paths, making them ideal for:

- Repetitive pallet moves

- Milk runs

- Heavy-load transport

- Line-side replenishment on fixed schedules

AGVs eliminate wait times and provide a constant, reliable cadence.

AMRs: Flexible, Intelligent, and Ideal for Dynamic Environments

AMRs outperform when workflows shift throughout the day. They’re perfect for:

- Dock-to-line material flow

- Kitting deliveries to multiple stations

- Ad-hoc replenishment

- Zone-to-zone transport in busy environments

AMRs recalculate paths in real time, avoiding human traffic, blocked aisles, or congestion — and they collect data that reveals hidden delays.

Together, AMRs and AGVs create a friction-free, predictable, and measurable workflow foundation.

Real-World Workflow Examples Where Bottlenecks Hide

1. Dock-to-Line Transport

The dock often becomes a holding zone because operators are busy elsewhere.

AMRs can automatically pick up inbound goods and deliver them directly to staging or line-side points, eliminating hours of accumulated delay.

2. Kitting and Sequencing

Kitting requires precision timing. When human operators batch tasks or are pulled away, kits arrive late.

AMRs ensure just-in-time delivery and reduce WIP clutter.

3. Replenishment & Material Refill

When forklift drivers multitask or routes get backed up, production lines starve.

AGVs running fixed replenishment cycles solve this by feeding lines at reliable intervals.

Each automated move generates data, revealing cycle times, route interference, congestion points, and causes of delay that were previously invisible.

Why Fixing Flow Beats Adding Headcount

Hiring more people does nothing to solve systemic workflow friction.

Automation, on the other hand:

- Removes non-value-added walking and travel

- Balances material flow across all stations

- Eliminates backlog caused by timing gaps

- Reduces forklift dependency and safety risks

- Standardizes movement and reduces human variability

- Provides real-time visibility into where (and why) delays occur

Once flow is stable, existing employees can focus on value-driven work, not transportation.

Improved flow makes your current workforce more effective without increasing overhead.

Ready to Uncover Your Hidden Bottlenecks?

Konnected Technology helps facilities discover and fix invisible workflow inefficiencies using AMRs, AGVs, and intelligent automation design.

→ Request a Workflow Assessment

Come visit us at www.konnectedtechnology.com and let us analyze your movement patterns, identify friction points, and show you how automation can transform your operational flow.